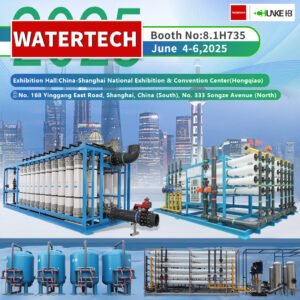

Industrial Seawater Reverse Osmosis Desalination Systems

Industrial Seawater Reverse Osmosis Desalination System (SWRO) is a reverse osmosis membrane filtration process that has been commercially used since the early 1970s accordingly. So, these systems can vary from big size desalination plants to a smaller sized seawater to drinking water machine. First of all, the typical single pass seawater treatment system consists of the following components:

- Intake: direct from sea or beach well water

- Pretreatment: Filtration and chemical dosing for example sand and carbon filter

- High pressure pump: to achieve pressure for swro membrane filtration

- Membrane assembly: to perform the desalination process for example DOW, Toray

- pH adjustment: to adjust the alkalinity or acid level

- Disinfection: to prevent any bacterial or organic growth for example uv sterilizer

Industrial Seawater Reverse Osmosis Desalination System Capacity Range:

Chunke industrial sea water desalination ro system is available with capacities ranging from 1000 LPH to 6.000.000 LPH and a maximum feed water TDS of 45.000 ppm accordingly. So, we offer standard industrial SWRO series plants as well as customizable to fit you water application needs. From your five-star resort to the world’s largest desalination plant, CHUNKE is ready and able to provide only the best in industrial desalination systems.

CHUNKE desalination machines are capable of removing salts as well as other impurities such as bacteria, sugars, proteins, dyes and constituents that have a molecular weight greater than 150-250 Dalton. So, CHUNKE supplies a full line of standard and customizable seawater reverse osmosis desalination systems with pretreatment and cip system.

What is the SWRO desalination system?

Thus, desalination systems have become an important process to supply freshwater. Desalination provides an alternative to insufficient clean water production and natural causes which exacerbates this issue such as droughts.

Seawater reverse osmosis systems uses reverse osmosis technology to purify dirt, minerals, bacteria, virus, salts and minerals from untreated water. This process works through applying high-pressure pumps that force the salty seawater water through semi-permeable membranes. Also, it consist of small pores that prevent the impurities from passing through. What results from the reverse osmosis system is fresh, clean water that is free of its pollutants which are simultaneously discharged.

You can use desalination systems generally in large-scale plants that must deal with country regulatory, company budgetary, and practical issues to produce economical and eco-friendly water distribution. So, there are hundreds of desalination plants throughout the world.

Industrial Seawater Reverse Osmosis System Flow Diagram:

Is SWRO Desalination system cost effective or not?

Seawater Reverse Osmosis Desalination machines are little expensive to build and operate over a long period of time consequently. However, recent development in water treatment components which includes reverse osmosis membrane advancements (high rejection, low energy costs) and energy recovery devices, have made the associated costs of desalination plants much lower. To such an extent that desalination machines have now become a cost-effective alternative source of water distribution. For this reason, most countries’ governments have started using them into their water plans as tools to help meet the present and future water goals accordingly.

What is the electrical power consumption of Industrial SWRO System?

Thus, it depends on capacity of swro water purifier plant as liter per hour or liter per day. So, our ro water treatment system power supply range is 220V to 480V with 50Hz or 60Hz.