Commercial Seawater Reverse Osmosis Watermaker Systems

CHUNKE produce a full range of yatch, boat and cruise commercial seawater reverse osmosis watermaker systems. So we design it for heavy-duty or continuous service within on and offshore applications requiring marine desalination systems.

What is commercial seawater desalination reverse osmosis water-maker system?

Hence, Seawater Reverse Osmosis Desalination Systems feature a unique and innovative compact design. Since, that allows for easy installation and operate in any size area. The high level corrosion resistant epoxy coated or stainless steel frame features. So a modular design that allows for the system to be divided into multiple assemblies for easier mounting. Meanwhile, the CK-SWRO series also have duplex SS centrifugal-type high pressure pump for high performance and corrosion resistance, a programmable computer PLC controller with many built-in features, 1000 psi fiberglass membrane housings for durability and high quality seawater membranes for pure product water.

How to customize/change size of commercial seawater desalination reverse osmosis system?

Our Commercial CK-SWRO series seawater ro water maker systems are available with capacities ranging from 100lph to 2000 lph and a maximum feed water TDS of 45.000 ppm. We produce standard commercial SWRO Series watermaker machines as well as customizable to fit you water application needs. Whether it’s for your luxury yacht, cruise line, commercial boat or for a five star resort on the beach, CHUNKE has the right desalination system for you project to rid of salt and gain tasty drinking water.

Can commercial SWRO inverse osmosis system install to boat ?

Producing fresh water is taken for granted in many regions such as in urban areas within developed countries. However, such locations do not afford people with the ease of attaining freshwater supplies in sufficient quantities to drink and use in other applications. For instance, arid areas where there is very less rain and remote islands throughout the world provide very few water sources to the people who inhabit these specific regions. One application which depends solely on the usage of a marine water maker for the production of freshwater is offshore installations. As ships cruise further offshore and away from any means of freshwater production from natural sources such as rivers, lakes, springs, and wells, the only real chance of getting clean water is from the ocean itself.

How does commercial SWRO marine water-maker work?

While the ocean provides a large amount of water to marine water boats, it contains extremely high level of salt, which makes it unusable in virtually any application, including consumption and drinking. To remedy this issue, boat owners that look to spend a great deal of time off-shore, make sure to carry a marine water maker on board in order to convert seawater into purified, freshwater. So, the water produced from marine water makers are of the highest quality and can be used for drinking, washing, showering, cleaning etc.

Commercial SWRO system process?

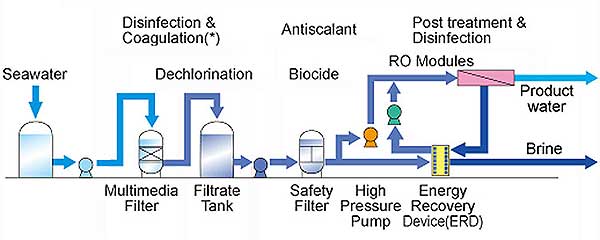

Primarily, a boat watermaker is using reverse osmosis water treatment system technology. Seawater firstly passes pretreatment unit, it includes media filter tanks, chemical dosing, cartridge filter housing. Second, pretreated water passes seawater swro membranes and they block salt, bacteria and viruses, after membrane process you gain fresh water.

Commercial Seawater Reverse Osmosis Watermaker System Flow Diagram:

What is the price or cost of seawater desalination swro system?

So, a commercial swro seawater reverse osmosis machine cost is largely dependend on feed water quality and the required product water quality.

The following list details many of the common pre and post treatment components:

- Chemical and pH dosing

- Chlorination dosing

- Media filter for example quartz sand

- Carbon filter for example activated carbon

- Water softener

- Antiscalant dosing

- Antofouling dosing

- Advanced controller for example Siemens

- Advanced instruments

- Iron removal filter for example freen sand

- TDS, pH, Conductivity monitoring

- Stainless Steel Skid or frame

- Blending systems

- Three phase electrical system and accessories

- PLC components for example Mitsubishi

- UV Sterilizer similarly ozone generator

- Furthermore, CIP (clean in place) membrane cleaning system