Industrial Reverse Osmosis (RO) Systems: Unlocking Efficiency and Quality

Industrial Reverse Osmosis RO systems remove up to 99.9% of salts and contaminates from different impure feed water sources. For example including tap, municipal, brackish and surface water. Consequently, the system does not allow bacteria, particles, sugars, proteins, dyes, and impurities. That is encompass a molecular weight of more than 150-250 Dalton passes to your permeate water.

Hence, CHUNKE produces a wide range of designed and custom industrial reverse osmosis systems. So it is ranging in capacity from 2000 to 180.000.000LPH to meet every industrial water treatment need and application. So, these energy efficient industrial RO equipment produces high-quality water at an affordable economic cost.

Furthermore, our industrial ro systems are delivering high quality water under the most difficult requirements of ongoing operation and corrosive conditions. Also we design them with selectable functional, control features and additional apparatus supplying user’s the capacity to custom-make your reverse osmosis machine. Whatever your water treatment application requires, our industrial reverse osmosis system will be your optimal solution.

Compact industrial inverse osmosis plant:

In addition, CK-RO Series industrial tap water reverse osmosis water treatment equipment is equipped with media filters. And chemical dosing systems (pre chlorination, antiscalant, dechlorination, post chlorination and post pH). So, this equipment is primarily customized to suit individual customers and different water applications. CK-RO Series is one of the most compact industrial reverse osmosis system on the market, built with energy saving 8040 ro membranes. accordingly

The design of the CK-RO Series skid mounted industrial reverse osmosis system, takes into consideration certain water problem. Along with it is robust construction, user friendly design, environmentally friendly material, economic, easy operating and long-term reliability.

Also you can choose your ro system as containerized reverse osmosis water treatment plant.

The process of industrial reverse osmosis machine:

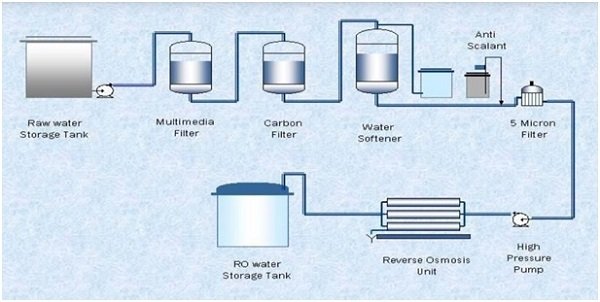

Industrial reverse osmosis plant includes a multimedia pretreatment tanks, water softener, antiscalant dosing system. And also it has antifouling dosing system, reverse osmosis unit with semi-permeable inverse osmosis membranes, ozone generator and ultraviolet sterilizers or post chlorination as a post treatment. These RO machines apply the new technology of reverse osmosis by sending feed water through a multimedia prefilter to remove particles that are larger than 10 micron. Then the water goesvia an antiscalant chemical to control hardness fouling that may cause damage to the membranes of the RO machine.

So, these pretreatment options have the capability of removing hardness, chlorine, odors, color, iron, and sulfur. The water then continues into the reverse osmosis unit where a high-pressure pump applies extreme pressure to the highly concentrated solution, separating the remaining salts, minerals, and impurities that the prefilter cannot catch. In addtion, fresh, potable water comes out from the low pressure end of the membrane while salts, minerals, and other impurities are discharged into a drain on the other end. Lastly, the water is passed through a UV sterilizer (or post chlorination) to kill any bacteria and microbes that still exist in the water.

Industrial Reverse Osmosis System Flow Chart:

What is the price of industrial reverse osmosis machine?

An industrial reverse osmosis purification system cost is largely dependend on feed water quality and the required product water quality.

The following list details many of the common pre and post treatment components:

- Chemical and pH dosing for example SEKO

- Media filter for example quartz sand

- Carbon filter

- Water softener

- Antiscalant dosing

- Advanced controller

- Advanced instruments

- Iron removal filter for example greensand

- TDS, pH, Conductivity monitoring

- Stainless Steel Skid or frame

- Blending systems

- Three phase electrical system and accessories

- PLC components

- Touch Panel for example Siemens

- CIP membrane cleaning system

What is the electrical power consumption of RO System?

It depends on capacity of ro water purifier plant as liter per hour or liter per day. So, our ro water treatment system power supply range is 220V to 480V with 50Hz or 60Hz.

In the realm of industrial water treatment, Reverse Osmosis (RO) systems have emerged as a leading technology to purify water, ensuring high-quality output while maximizing efficiency. RO systems have proven indispensable in various sectors, including manufacturing, power generation, pharmaceuticals, and food and beverage production. This essay delves into the world of industrial RO systems, exploring their significance, working principles, benefits, and key considerations for effective implementation.

Understanding Industrial Reverse Osmosis Systems

Industrial RO systems employ a process called reverse osmosis to purify water by removing impurities, contaminants, and dissolved solids. This technology utilizes a semi-permeable membrane that allows water molecules to pass through while rejecting dissolved solids, salts, and other unwanted particles. By exerting pressure on the feedwater, RO systems drive the water molecules against the concentration gradient, resulting in the separation of impurities and pure water.

Working Principles of Industrial RO Systems

An industrial RO system comprises several key components that work together to deliver clean water. Firstly, the pre-treatment stage involves the removal of larger particles, sediments, and organic matter through processes like filtration, sedimentation, and activated carbon adsorption. This helps protect the RO membrane from fouling and damage.

Next, the pressurization stage forces the pre-treated water into the RO membrane using a high-pressure pump. The semi-permeable membrane acts as a barrier, allowing only pure water molecules to pass through, while rejecting dissolved solids and contaminants.

The purified water, known as permeate, is collected and stored for use, while the concentrated wastewater, known as brine or reject water, is discharged from the system. Some advanced RO systems incorporate energy recovery devices to optimize efficiency by reusing the energy contained in the brine stream.

Benefits of Industrial RO Systems

High Water Quality: Industrial RO systems effectively remove a wide range of impurities, including heavy metals, salts, bacteria, and organic compounds. This ensures that the treated water meets stringent quality standards and is suitable for various industrial processes, ultimately enhancing product quality and safety.

Water Efficiency: RO systems have a high water recovery rate, typically ranging from 50% to 80%. This means that a significant portion of the feedwater can be converted into permeate, minimizing water wastage and reducing the overall water footprint of industrial operations.

Cost Savings: Implementing RO systems can lead to substantial cost savings in the long run. By producing purified water on-site, industries can avoid the expenses associated with purchasing and transporting large volumes of water. Additionally, the removal of contaminants and dissolved solids can prevent scaling and corrosion issues, reducing maintenance and equipment replacement costs.

Environmental Sustainability: Industrial RO systems contribute to environmental sustainability by conserving water resources and reducing the discharge of pollutants into ecosystems. By adopting RO technology, industries can align with sustainable practices and meet regulatory requirements, fostering a positive reputation and responsible corporate image.

Considerations for Effective Implementation

To ensure optimal performance and longevity of industrial RO systems, several considerations should be taken into account:

System Design: Proper system design, including accurate sizing, selection of appropriate membranes, and consideration of operational conditions, is crucial to achieving desired outcomes. Engaging with experienced professionals and reputable manufacturers is recommended to ensure an efficient and reliable system design.

Pretreatment: Effective pretreatment is essential to protect the RO membrane from fouling, scaling, and premature deterioration. Adequate prefiltration, pH adjustment, and chemical dosing systems tailored to the feedwater characteristics are necessary to optimize system performance.

Monitoring and Maintenance: Regular monitoring of system parameters, including pressure, flow rates, and water quality, is vital for detecting any deviations or issues