Since the early 1960s, Reverse osmosis system for dialysis or hemodialysis (HD) has been increasingly used for the treatment of acute renal failure and end-stage renal failure. Technologic advances in dialyzer membranes, dialysis machines and vascular access have made HD a routine procedure today.

What is dialysis water treatment?

Dialysis is a blood cleaning process used when a person kidneys doesn’t work or have a reduced functionality (around 10 to 15%). The procedure consists of an artificial kidney or dialyzer where the blood contaminants are filtered through a thin membrane into a concentrate fluid called dialyzate in dialysis water treatment.

The dialyzate is a mix of: bicarbonate componente, that can be sodium bicarbonate and sodium chloride; acid component, that contains chloride salts of sodium, potassium (if needed), calcium, magnesium, acetate (or citrate), and glucose (optional); and ultra pure water as a mixing media.

Why Dialysis machine needs reverse osmosis?

Dialysis water treatment or dialysis machines need ultra pure water to prevent patients from getting infections from micro-organisms in the water. That’s why CHUNKE produces reverse osmosis systems for dialysis machines.

The ultra pure water needs vary depending on the capacity of the dialysis center and treatment of each center. So, CHUNKE had delivered different types of reverse osmosis systems for dialysis to cover all needs for this high standards of water quality.

Who invented the first reverse osmosis system?

Eighteenth-century French physicist Jean Antoine Nollet gets the credit for that. However, two centuries after Nollet’s discovery, RO was still not much more than a laboratory phenomenon until a Thayer student project helped create a new multi-million dollar RO industry. Now, dialysis water treatment becomes one important area in water treatment industry.

What is the process for purifying water for dialysis treatments?

A reverse osmosis (RO) system is the primary method for purifying water for dialysis treatments, ensuring patients receive safe, clean water. However, even before the water passes through the RO machine, it receives a preliminary filtration via a pre-treatment system, helping remove chlorine, chloramines, and other contaminants, and lessening the burden of the RO membrane. The pre-treatment system can also help identify a drop in pressure or a leak.

Why does tap water have a risk for dialysis patients?

Tap water does not meet the standards required for dialysis water treatment due to the chemicals water municipalities add to the water to make it safe to drink. These chemicals include flocculants such as aluminum sulfate, fluoride, and polyphosphates to reduce corrosion, as well as various disinfectants, such as ozone, chlorine dioxide, chlorine, and chloramines. As I mentioned before, these chemicals can be harmful to dialysis patients since their kidneys are unable to filter the contaminants from their body. So, dialysis water treatment is important for hospital in dialysis application.

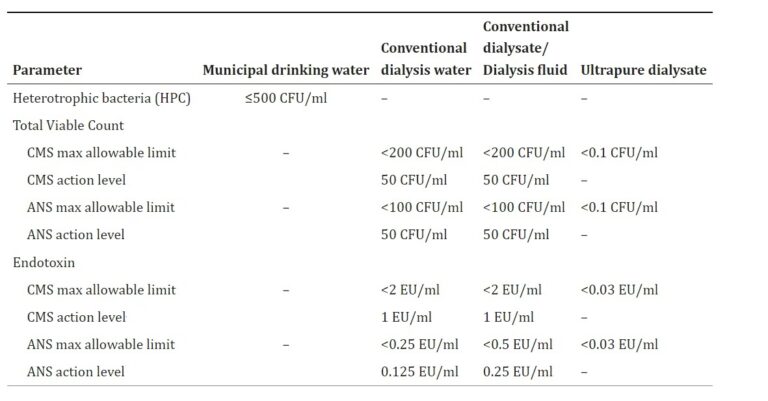

What are the national standards for water quality in dialysis treatments?

The Association for the Advancement of Medical Instrumentation® (AAMI) and the International Organization for Standardization (ISO) established chemical standards for water used in dialysis, including the equipment and processes, the devices used for storage and distribution of the water, and the threshold levels of water contamination. It is critical that we provide patients with purified water that meets or exceeds these chemical and microbiological standards. Reverse osmosis system for dialysis provides best water for you.

Chunke reverse osmosis system for dialysis

Chunke experienced engineering team are designing and producing reverse osmosis system for dialysis. We have different option to reach national standards.

1. Basic Reverse Osmosis System for Dialysis

2. Middle Grade Reverse Osmosis System for Dialysis (SS304)

3. Upper Grade Reverse Osmosis System for Dialysis (SS316)

4. Advanced Grade Reverse Osmosis System for Dialysis with Electrodeionization

In advanced grade reverse osmosis system for dialysis, we are adding Electrodeionization (EDI) module into the system. Also in this system, we use double pass reverse osmosis system.

What are the benefits of adding a heat disinfection unit?

The heat disinfection module can enhance the chemical disinfection’s ability to mitigate a microbial growth, thus adding additional protection to the reverse osmosis system for dialysis. We can perform a temperature-controlled disinfection of the permeate ring main, which helps prevent biofilms and endotoxin buildup. This improves microbial control and reduction of biofilm without additional chemical disinfections. It also handles four machines at a time, which means you can ensure that all your machines are disinfected in one night.

What is the parts of reverse osmosis system for dialysis or hemodialysis?

1. Sand Filter or Iron removal filter

The exact combination and configuration of components of a water treatment system will, amongst various factors, depend on the quality of the feed water. In some regions where the feed water has a high content of iron, an iron removal filter is necessary. Iron removal filters remove suspended and dissolved iron by green sand and alkaline dolomitic rocks. Green sand facilitates the oxidation of ferrous salts to the insoluble ferric hydroxide. The alkaline reaction on the surface of the alkaline rocks then enables the direct removal of iron by trapping it in the hydroxide form. The hydroxides retained can easily remove by back-washing regularly.

If you do not have iron problem, standard sand filter is enough for you to get good pretreatment result. So, sand filter is important role to expand reverse osmosis membrane life in dialysis water treatment.

2. Granular activated carbon filters

Granular carbon (charcoal) activated by heat treatment will adsorb chlorine, chloramines and other organic substances from water. Meanwhile, activated charcoal also removes chlorine by a catalytic action, resulting in the conversion of chlorine into hydrochloric acid that is neutralized by the bicarbonates in the water. Chlorine hurts membranes and chloramines hurt patients (chloramines are oxidants and react with oxygen to destroy cell walls, including red blood cells causing hemolytic anemia). Feed water must remain in contact (empty bed contact time) with the carbon long enough to allow adequate removal of chloramines.

The U.S. Food and Drug Administration (FDA) recommends a minimum of 10 minutes of empty bed contact time. The FDA also recommends that two tanks filled with activated carbon be used in series. When the first filter has a chloramine concentration in the effluent > 0.1 mg/L, it should be replaced and if the chloramines level in the effluent of the second tank exceeds 0.1 mg/L, the water must not be used for dialysis. Since carbon filters are highly porous with a high affinity for organic materials, they can contaminate with bacteria if they are not serviced properly or replaced frequently.

3. Water softeners and deionizers

Calcium and magnesium, the hardness-forming ions in water, can cause precipitate to form and clog equipment as well as damage the reverse osmosis (RO) membrane. To eliminate these problems, feed water must be softened. This is carring out by means of an ion exchange process, which removes from feed water inorganic ionic contaminants. Water softeners and deionizers are both ion exchangers. In this process, water is rinsed through a column containing synthetic spheres, called “resins”. Certain ions present in water are exchanging for other ions fixed to the resins. Water softeners contain sodiumcoated resins and these are exchanging mainly for calcium and magnesium ions.

Water softeners have a more limited binding capacity for other polyvalent cations like iron, manganese and aluminium. On the other hand, deionizers differ from water softeners in that they contain both cation and anion exchange resins. Cations are exchanging for hydrogen (H+) ions and anions are exchanging for hydroxide (OH-) ions. The H+ and OH- then combine to form H2O. Hence, it removes all types of cations and anions for pure water. Deionizers produce the purest water in terms of ionic contaminants. But at the same time, they harbor bacteria and produce significant colloidal material. Deionizer tanks should monitor with resistivity meters and produce water that always exceeds 1 MΩ/cm in resistance. When the exchange sites on a resin bed are depleted, the bed is to be exhausted and needs to be regenerated.

Water softeners are regenerating by flushing the resin bed with water and then with a brine of sodium chloride (a concentrated salt solution). If regeneration is not performing at the appropriate intervals before exhaustion, previously adsorbed ions may elute into the effluent, causing ionrelated toxicities. Reports of fluoride and copper intoxications have appeared as a consequence of unrecognized deionizer exhaustion.

4. PP Cartridge Filters

All feed water contains particles. Meanwhile, these particles can cause downstream dialysis equipment malfunction by clogging orifices and valves. Filters remove particles, solutes and other substances above a given size by mechanical filtration. So, there are different types of cartridge and bag filters available, and these are rated by the filter pore size, which is microns. Five-µm filters are generally good as the size necessary to provide adequate water treatment and protection for equipment accordingly.

5. Reverse osmosis

The primary water purification process of choice in most applications is RO. So, it applies the rejection characteristics of ion exclusion semi-permeable membranes. In normal osmosis, water molecules will flow from areas of lesser solute concentration to that of greater concentration until the fluid concentration on both sides of the membrane is equal. Essentially, natural osmosis tries to dilute the side with the higher salt concentration to a point where both sides of the semi-permeable membrane have equal osmotic pressure.

RO overcomes osmosis and concentrates salts on the reject side of the membrane, while collecting pure water on the product side. So, this is accomplishing by applying high hydrostatic pressure to the feed water and driving water across the membrane. The end result is the production of purified water. Hence, this process can reject 90% to 99% of ionic as well as microbiologic contaminants, including bacteria, endotoxins, viruses, salts, particles and dissolved organic substrates. Depending on the quality of the source water, RO Plant generally produces water that is safe for dialysis; otherwise, it may be necessary to polish the RO product water with a deionizer.

If you have question or if you want to get quotation, please feel free to fill in below form and contact with us. Our technical sales team will contact with you in 24 hours.