Today, we will talk about Big-Scale Reverse Osmosis Systems, accordingly. Water scarcity is a critical issue that affects regions across the globe. As the demand for clean and purified water continues to rise, industries and municipalities are turning to innovative solutions to meet this challenge. So, one such solution is the implementation of big-scale reverse osmosis systems. Hence, these industrial water treatment plants are designed to produce large volumes of high-quality water by removing contaminants and dissolved solids. In this comprehensive guide, we will explore the history, operation, advantages, and applications of big-scale reverse osmosis systems, accordingly.

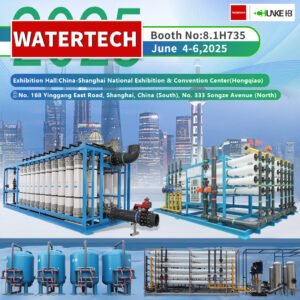

CHUNKE Big-Scale Reverse Osmosis Systems Project

500m3/hour Reverse Osmosis System in China

A Brief History of Reverse Osmosis

Reverse osmosis, although discovered in 1748 by French physicist Jean-Antoine Nollet, was initially confined to laboratory settings. So, it wasn’t until the mid to late 1950s that researchers began developing asymmetric membranes with thin film technology, making reverse osmosis systems more practical. Over time, these systems became increasingly sophisticated and efficient, playing a pivotal role in the purification and processing of various liquids, with a primary emphasis on water.

Understanding the Reverse Osmosis Process

To grasp the concept of reverse osmosis, we must first understand osmosis itself. So, osmosis is a natural process where a solvent, such as water, moves from an area of low solute concentration to an area of high solute concentration through a semi-permeable membrane. Reverse osmosis, on the other hand, is the process of applying pressure to force a solvent with high solute concentration through a semi-permeable membrane to an area of lower solute concentration. This process effectively removes dissolved solids and contaminants from the water, producing purified water.

Components of a Complete Reverse Osmosis System

A complete reverse osmosis system consists of various components working in harmony to ensure efficient water treatment. So, these components include pre-treatment systems, the reverse osmosis unit, storage and distribution mechanisms, post-treatment systems, and instrumentation for monitoring water quality. Let’s explore each component in detail:

Pre-Treatment Systems

Pre-treatment is a crucial step in the reverse osmosis process, as it prevents membrane fouling and enhances the overall efficiency of the system. First of all, pre-treatment systems typically include:

- Multi-media Filter: This filter removes large debris, sediment, and particles from the feed water, ensuring the smooth operation of the reverse osmosis membranes, accordingly.

- Carbon Filter: The carbon filter eliminates chlorine, organic compounds, and other contaminants that could damage the membranes.

- Softener: In areas with hard water, a water softener is used to remove minerals like calcium and magnesium, preventing scale formation on the membranes, accordingly.

- UV Sterilizer: UV sterilization kills bacteria, viruses, and other microorganisms that may be present in the feed water, safeguarding the reverse osmosis membranes.

- Ozone Generator: Ozone is a powerful oxidant that effectively disinfects water and eliminates organic compounds, providing an additional layer of protection to the membranes, accordingly.

Reverse Osmosis Unit

The heart of the system is the reverse osmosis unit itself. It consists of high-quality membranes that remove dissolved solids and contaminants from the water. So, these membranes are carefully selected from renowned manufacturers to ensure optimum performance and durability. The reverse osmosis unit is designed to handle large volumes of water, making it ideal for industrial applications, accordingly.

Storage and Distribution

As the reverse osmosis process produces water gradually, a storage tank is necessary to store the purified water. So, there are two types of tanks commonly used: atmospheric tanks and bladder tanks. Meanwhile, atmospheric tanks, although larger in size, offer higher water quality due to the absence of a bladder. Bladder tanks, on the other hand, are more compact and suitable for smaller systems, accordingly. To distribute the water, a re-pressurization pump is used to ensure a steady flow to the desired points of use.

Post-Treatment Systems

Post-treatment is an essential step to enhance the quality and stability of the purified water. Common post-treatment methods include:

- pH Adjustment: This process raises or lowers the pH of the water to the desired level, optimizing its compatibility with subsequent processes or applications.

- Deionization: Deionization removes remaining ions and minerals from the water, producing ultra-pure water suitable for specialized applications such as laboratory use or semiconductor manufacturing.

- UV Disinfection: UV disinfection utilizes ultraviolet light to destroy any remaining bacteria, viruses, or microorganisms in the water, ensuring its microbiological safety.

Instrumentation and Monitoring

To monitor and maintain the quality of the purified water, several instruments and analyzers are employed. So, these instruments measure parameters such as pH, conductivity, and temperature, providing real-time data for process control and adjustment.

Storage and Distribution

Advantages of Big-Scale Reverse Osmosis Systems

Big-scale reverse osmosis systems offer numerous advantages that make them an ideal choice for industrial water treatment. Here, some of the key advantages include:

1. High Water Production:

These systems can produce large volumes of purified water, making them suitable for industrial and municipal applications with high water demand.

2. Exceptional Purity:

Reverse osmosis is highly effective in removing dissolved solids, contaminants, and microorganisms, resulting in water of exceptional purity, accordingly.

3. Cost-Effective:

Reverse osmosis is an economical water treatment technology compared to other purification processes, providing a reliable and affordable source of high-quality water.

Customization Options:

Big-scale reverse osmosis systems can be tailored to meet specific requirements and conditions, ensuring optimal performance and efficiency in diverse applications, accordingly.

Reliable Operation:

Built with high-quality components and designed for long-term operation, these systems offer reliability and minimal maintenance requirements.

Applications of Big-Scale Reverse Osmosis Systems

Big-scale reverse osmosis systems find applications in various industries and sectors where a large volume of purified water is required. Some common applications include:

- Seawater Desalination: Reverse osmosis systems are used to convert seawater into fresh water, providing a sustainable solution for regions facing water scarcity near coastal areas.

- Brackish Water Desalination: These systems are also effective in treating brackish water, which is characterized by higher salt content than freshwater but lower than seawater.

- River Water Purification: Reverse osmosis systems can be utilized to purify river water, removing contaminants and impurities to meet the quality standards required for various industries, accordingly.

- Well Water Treatment: Well water often contains high levels of dissolved solids and contaminants. Reverse osmosis systems can effectively treat well water, ensuring its suitability for consumption and industrial use.

- Industrial Processes: Many industrial processes, such as food and beverage production, pharmaceutical manufacturing, and power generation, require large volumes of purified water. So, big-scale reverse osmosis systems provide a reliable source of high-quality water for these applications.

Designing and Sizing a Big-Scale Reverse Osmosis System

Designing and sizing a big-scale reverse osmosis system requires careful consideration of various factors:

- Feed Water Characteristics: Understanding the composition and quality of the feed water, including hardness, TDS (Total Dissolved Solids), chlorine levels, and other contaminants. It is crucial for selecting the appropriate pre-treatment methods and sizing the system.

- Capacity Requirements: Determining the desired water production capacity is essential to ensure that the reverse osmosis system meets the demand. Factors such as peak usage, future expansion, and seasonal variations should be taken into account.

- Pre-Treatment Optimization: Proper pre-treatment, such as multi-media filtration, carbon filtration, and softening, is vital to protect the reverse osmosis membranes and optimize system efficiency.

- Storage and Distribution: Selecting the appropriate storage tank size and distribution mechanisms ensures a consistent supply of purified water to meet the demands of the application.

- Post-Treatment Considerations: Depending on the specific requirements of the application, post-treatment options such as pH adjustment, deionization, and UV disinfection may be necessary to achieve the desired water quality.

Maintaining and Supporting Big-Scale Reverse Osmosis Systems

To ensure the long-term performance and reliability of big-scale reverse osmosis systems, proper maintenance and support are essential. So, regular membrane cleaning, replacement of worn-out components, and monitoring of system performance are crucial for optimal operation. Hence, choosing a reputable supplier who offers comprehensive support, including emergency assistance and spare parts availability, is vital for the smooth functioning of the system.

Conclusion

Big-scale reverse osmosis systems have revolutionized the way we approach water treatment on a large scale. With their ability to produce high volumes of purified water. These systems are indispensable in addressing water scarcity and meeting the demands of various industries and municipalities, accordingy. By harnessing the power of reverse osmosis technology, we can ensure a sustainable and reliable source of clean water for generations to come.

Remember, when considering the installation of a big-scale reverse osmosis system. It is essential to consult with experienced engineers and professionals to design a system that meets your specific needs and requirements. With their expertise and guidance, you can implement a customized solution that provides efficient and cost-effective water treatment for your industrial applications, accordingly.

By investing in a big-scale reverse osmosis system, you are not only enhancing the quality of your water supply but also contributing to a more sustainable and water-secure future.