Here, we will explain how seawater desalination work with reverse osmosis membrane filtration technology.

You will know all details how to desalinate sea water or ocean water with RO Plant. How to intake sea water, how to send RO desalination plant.

World’s population continues to increase and develop. So, our freshwater resources become increasingly scarce. We are lucky, because Earth’s Ocean and Seas offer an alternative and can provide a sustainable supply of drinking water. As a result, we can convert sea water to fresh drinkable water through a process known as sea water reverse osmosis desalination process.

Firstly, process starts sucking sea water from sea or ocean directly or using wells located on shoreline. To intake water from sea or ocean, we have some solutions accordingly.

How to Intake Sea Water for Reverse Osmosis Desalination Plant?

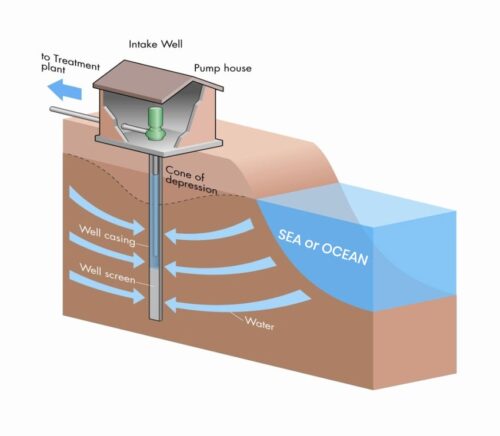

1. Shoreline, Coast or Beach Well Intake

Shoreline Well intake method is best solution for you to reduce running cost of sea water desalination plant. In this method, you have to open a well near to sea. As you know that seacoast has sand or gravel, and they are best filter material also. Naturally, your water is filtering, and you rid of turbidity and bigger particles. So, compare with intaking directly from sea, it solves a lot of problem. When you intake sea water directly from sea, as you know you also transfer fishes, shrimps, sea moss, trashes and a lot of other things to your sea water storage tank or pool accordingly.

The intake facilities and construction of intake structure both have important impact on seawater desalination plant investment, production cost, system operation stability and ecological environment. Investment of seawater desalination, scale of construction, and process for water quality requirements should take into consideration while developing intake projects. At the same time, we select water intake and its facilities based on hydrology water quality in intake area, geology conditions, meteorological data and natural disaster.

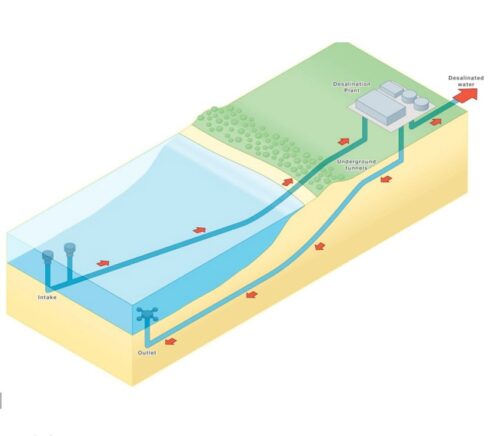

2. Subsurface Water Intake

The deep seawater of open ocean is delivered to the shore-side through building intake pipes and then supplied to desalination project by pump plant constructed in the coastline, this is “subsurface water intake”. Generally speaking, when sea level below 1~6m, intake water contains small fish, water grass, seaweed and other microorganism, hence, water quality is not good. The content of these materials is 20 times reduction when intake level is above beneath sea level 35m, and water quality is good, which can greatly reduce the operating cost of the pre-treatment equipment. Meanwhile, water temperature in subsurface is lower, benefit to thermal seawater desalination process. This kind of intake is usually adopted on areas where seabed is quite precipitous, which is within 50 m from the coast and water depth up to 35 m.

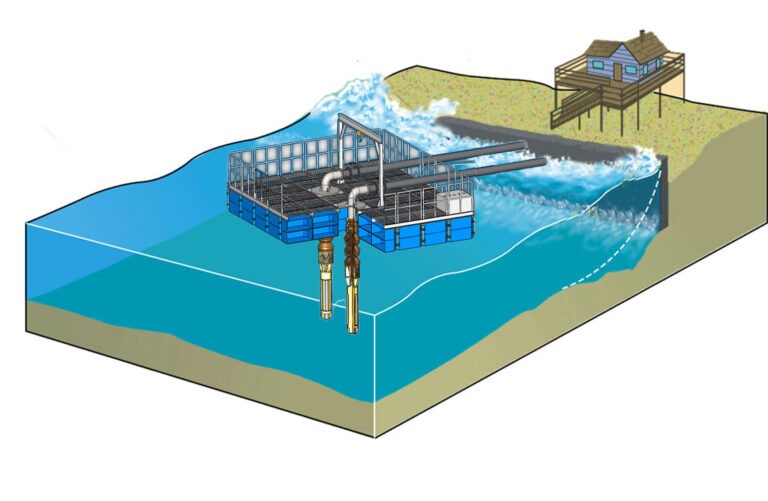

3. Open Sea Water Intake

Open sea water intake is the most common intake project. Although its water quality not good, it is still widely adopted due to advantages of small investment, wide application range and full application experience. Because you just need a floating pump, put it on sea serface and intake sea water to your storage tank or pool.

Which method you choose is dependent on your budget, your geological and meteorological condition. After we check your project, we can suggest to you most suitable method. How seawater desalination work article. also help you to understand.

How to storage sea water ?

Depends on your projects size, you can storage water in tanks or pool. And also depens on your water quality maybe need some chemical and physical treatment. Floculation, chlorination, sedimentations are mostly used method.

Filtering sea water with multi-media filters

After storage tank or pool, to increase life of reverse osmosis membrane, we insist on suggesting to use multi-media filters to remove small particles which reduce your treated water quality and life of reverse osmosis membrane. Also, pretreatment help to remove odor, taste from your seawater.

What is Multi-Media Water Filter in water treatment?

Multi-Media Water Filter is a process that uses one or several filter media to pass high-turbidity water or high TSS (total suspended solid) water through a certain size of granular or non-granular materials to effectively remove suspended impurities and filter the water. The filter material can be quartz sand, anthracite, manganese sand, etc. It is mainly used for water treatment to remove turbidity, biger particles, moss, seaweed, shrimps and other sea creatures.

The multi-media filter is mainly composed of the following parts: supporting pipelines and valves and booster pumps. The filter body includes:

- FRP or Carbon Steel Tanks: Because of corrosive effect of salty sea water, we are using FRP (Fiber glass reinforced plastic) or Rubber Isolated Carbon Steel Tanks.

- Backwash air pipe

- Water distribution component

- Support component

- Filter material

- Exhaust valve (external)

To understand how seawater desalination work, we check deeper. Inner filter layer composition: The multi-media filter material in the filter is high-quality uniform grain gravel, quartz sand, magnetite, manganese, anthracite, etc. The filter material is scientifically and orderly in the filter tank according to its specific gravity and particle size Distribution, such as anthracite with a small specific gravity and slightly larger particle size is placing in the uppermost layer of the filter bed, quartz sand with a moderate specific gravity and small particle size is placing in the middle layer of the filter bed, and gravel with a larger specific gravity and larger particle size is placing in the lowermost layer of the filter bed.

Quartz Sand Filter

Quartz sand filter is a kind of filter that uses quartz sand as filter material. It can effectively remove suspended matter in water, and has obvious removal effect on colloid, iron, organic matter, pesticide, manganese, bacteria, virus and other pollutants in water. It has the advantages of low filtration resistance, large specific surface area, strong acid and alkali resistance, oxidation resistance, good pollution resistance, etc. The unique advantage of quartz sand filter lies in the optimization of filter material and filter The design of the filter realizes the adaptive operation of the filter, and the filter material has a strong self-adaptability to the raw water concentration, operating conditions, pre-treatment process, etc.

The quartz sand filter has the advantages of simple structure, automatic operation, large flow rate, few backflushing times, high filtration efficiency, low resistance, and convenient operation and maintenance.

After multi-media filters, to be sure not any sand particles from multi-media filters or some smaller particles which is less than 10 or 5 micrometer come to reverse osmosis membrane, we are using cartridge filters.

What is cartridge filter housing?

Cartridge Filter Housing is a set of cylindrical tank and several cartridge filters inside it, which we mostly use in the pre-treatment stage of water treatment systems by reverse osmosis. The ability to remove suspended particles in water and other fluids by various types of cartridge filters is one of the main reasons for designing cartridge filter housings that prevent damage to RO membranes.

After our sea water passes all these pre-treatment, it is ready to go Reverse Osmosis Membrane Filtration System to remove salt and all micro level impurities from sea water to gain fresh potable water.

What is reverse osmosis system?

Reverse osmosis is a water purification process that uses a semi-permeable membrane (synthetic lining) to filter out unwanted molecules and large particles such as contaminants and sediments like chlorine, salt, and dirt from drinking water.

Reverse osmosis water filtration systems use RO membrane technology.

What is reverse osmosis (RO) membrane?

As you see from photo, this is an ro membrane, there are a lot of suppliers for it so there are different quality membranes in market. In Chunke , we are always using good and high quality membranes in our project. We explain the model of 8040 type membranes, 8 referse the diameter as inch, this membrane diameter is 7.9inch, this is universal standard and length of the membrane is 40 inch, so this size is called for all brand membranes are 8040.

As you see there is a frp shell out of membrane, but membrane is inside of this shell. To understand how seawater desalination work, we check more.

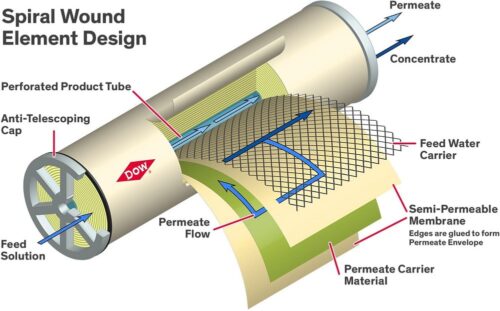

From below figure, we see how is RO membrane structure?

Layers of RO Membrane

Reverse osmosis membranes are constructed from a membrane flat sheet, it is comprised of three layers:

1. Polyester fabric support base

2. Micro porous polysulfone layer

3. 0.2 micron thickness polyamide barrier layer

The polysulfone lair strengthens the very thin barrier layer. So, it allows water to pass through while preventing other compounds from passing through membranes. As a result. it removes molecules based on their size shape and charge, generally contaminants larger than water molecules will not pass through including most chemical contaminants and all microorganisms such as viruses and bacteria.

Feed Spacer

The membrane flat sheet is combining with a sheet of feed channel spacer. This provides turbulence and creates space between the membrane sheets for the feed water. Hence, a sheet of permeate spacer is added to the membrane sheets and feed channel spacer. So, this enables the final recycled water product or permeate to flow evenly across the entire membrane surface even under high pressure.

So, the back of the membrane is completely sealed to the edges of the permeate spacer. Hence, the membrane sheets are glued along each of the three exposed sides and rolled around the core tube. So, feedwater is forced through the feed channel spacer and into the barrier layer of the membrane, water passes through the membrane surface into the permeate channel. Hence, it flows in a spiral direction and collects in the core tube, this water is the final recycled water product or permeate. As a result, you remove salt from seawater or ocean water. Hence, now you are clearer about how seawater desalination work.

So we put this membrane in membrane housing inside, membrane type and size depends on your water source, capacity, application.

To understand more about reverse osmosis system and how reverse osmosis system work, please watch our video from below.

After reverse osmosis sea water desalination system, your water is ready to drink. Hence, it is clean, safe and tasty water.

To get more details about sewater desalination system and how seawater desalination work, please check our commercial sea water desalination systems and industrial seawater desalination systems from below:

Capacity Range: 2m3 to 38m3/Day

Membrane Diameter: 2.5″-4″

Working Pressure: 700-1000psi

Feed Water TDS: 20000-40000ppm

Capacity Range: 38m3 to 2500m3/Day

Membrane Diameter: 8″

Working Pressure: 1200psi

Feed Water TDS: 20000 to 40000ppm