We, here, make detailed explanation for Reverse Osmosis Plant Diagram known as reverse osmosis process flow diagram. We are Chunke Water Treatment, a top water treatment system maker from Guangzhou, China. We focus on Reverse Osmosis Systems, Ultrafiltration Systems, and more. So, our team is great at making clear reverse osmosis plant diagrams.

These diagrams help show how to clean water by removing solids and impurities. This method is key in industries for cleaning water used in processes, boilers, and cooling towers. You can see how it works with a detailed ro system infographic.

If you want to set up a reverse osmosis system, check our website. We have a detailed guide on how to install a reverse osmosis system. Our team at Chunke Water Treatment is here to help with your water treatment needs. A good reverse osmosis plant diagram is key to understanding the process and making sure it works well.

Important Points

- Industrial reverse osmosis systems are used to remove dissolved solids and impurities from water.

- A reverse osmosis plant diagram is a visual guide to understanding the water treatment process illustration.

- Our team at Chunke Water Treatment specializes in designing, engineering, and manufacturing Reverse Osmosis Systems.

- A well-designed ro system infographic is crucial for the effectiveness of the water treatment process.

- Regular maintenance is essential for the longevity and reliability of industrial RO systems.

- Approximately 70% of the Earth’s surface is covered by water, but only 3% of that is fresh water, making water treatment a critical process.

- Solar-powered reverse osmosis systems can remove approximately 98% of salt from brackish water, providing a sustainable solution for water treatment.

Understanding the Evolution of Reverse Osmosis Technology

Exploring reverse osmosis, we see a big change in technology. The historical development of RO systems has seen major steps forward. These changes have made water purification better, thanks to new ro plant layout design, filtration system schematic, and water purification diagram.

The need for clean drinking water has driven RO system development. Researchers have worked hard to make RO systems more efficient. Now, RO systems are used in many fields, like water treatment and food and beverage.

New advancements in RO technology are exciting. For example, thin-film composite membranes are more effective and last longer. Also, energy-recovery devices have made RO systems more eco-friendly. As we keep improving RO technology, we’ll see even more breakthroughs.

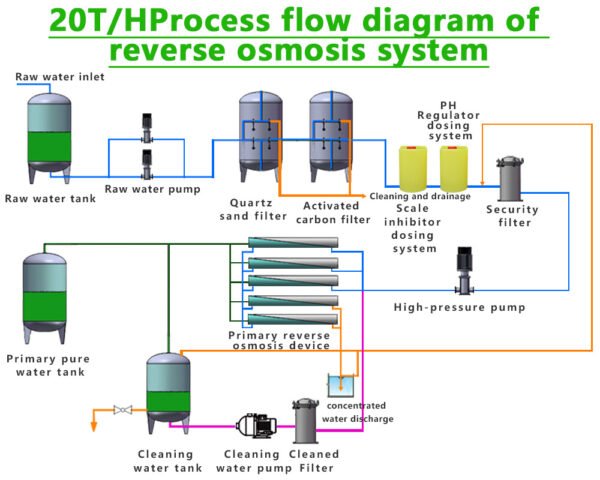

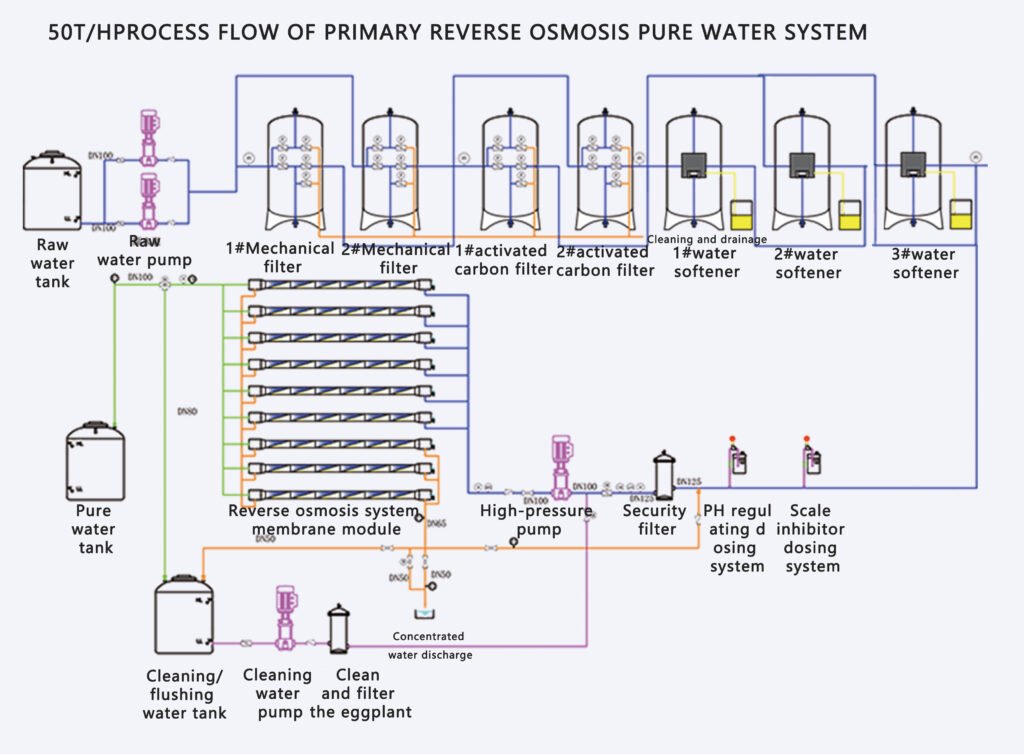

Key Components of a Reverse Osmosis Plant Diagram

Understanding a reverse osmosis plant is easier with visualization. The ro plant components visualization shows the parts that clean water. The osmosis process flowchart outlines water’s journey through the system.

The system includes pre-filters, RO membrane, post-filter, and bladder tank. Each part is crucial for cleaning water. Pre-filters remove big particles, and the RO membrane filters out 95% of impurities.

A detailed diagram of the plant helps us understand it better. It shows how each part works together. By looking at the ro plant components visualization and osmosis process flowchart, we learn about the reverse osmosis process.

Reverse osmosis systems remove many contaminants. They work best at 65 PSI and 77°F (25°C). Knowing about the osmosis process flowchart and ro plant components visualization shows how effective they are in cleaning water.

Pre-treatment System Configuration

Our pre-treatment systems remove impurities from water, making the reverse osmosis process more efficient. A good water treatment process illustration shows the needed steps. The setup of the pre-treatment system is key to the RO system’s success.

The pre-treatment system has filters, chemical treatments, and monitoring systems. These parts work together to clean the water and protect the RO membrane. A ro system diagram for water treatment gives a clear view of how it’s set up.

Some important parts of the pre-treatment system are:

- Filtration stages: removing dirt and contaminants

- Chemical treatment processes: adjusting pH and removing scaling agents

- Monitoring systems: tracking water quality and system performance

Knowing about the pre-treatment system’s setup and parts helps us improve the RO system’s performance. This ensures we get high-quality water.

Core Membrane Technology Explained

Our reverse osmosis definition focuses on making water safe and clean. At the center of this is the core membrane technology. It’s key to removing bad stuff from water, making it safe to drink. The ro plant definition shows how important this technology is for the whole process.

The core membrane technology uses special membranes to filter out impurities. These membranes have tiny holes that let water through but block bigger stuff. By applying pressure, water is pushed through these membranes, leaving it clean. This tech can remove up to 99% of harmful stuff like arsenic and chlorine.

Some key features of core membrane technology include:

- High rejection rate of impurities

- Low energy consumption

- Long membrane lifespan

- Easy maintenance and replacement

Our ro plant definition emphasizes the role of membrane technology. It shows how core membrane technology makes water purification possible. This tech is vital for removing impurities and giving us clean drinking water.

High-Pressure Pump Systems and Their Role

Our high-pressure pump systems are made to work well and reliably in reverse osmosis plants. The ro system infographic shows how key these pumps are in water treatment. They ensure a steady flow to the RO elements. With more than 14,451 desalination plants worldwide, efficient pumps are more crucial than ever.

A water treatment process illustration can show how high-pressure pumps fit into the big picture. They boost water pressure so it can remove impurities effectively. Since energy costs make up about 50% of a plant’s yearly expenses, these pumps must be very efficient.

- Pump type and application: Centrifugal pumps are often used in RO systems with pressures below 400 psig. Multi-stage centrifugal pumps can raise water pressure by up to 30 psi with each stage.

- Energy efficiency: Traditional pumps are about 83% efficient. But tilting pad pumps can reach 85% efficiency.

- Maintenance requirements: Regular upkeep is key to keep pumps running well and lasting longer.

Knowing how high-pressure pump systems work helps us design better systems. This leads to cost savings and a greener water treatment process.

Post-Treatment Process Integration

Our post-treatment systems are made to purify water to the highest quality. They go through several steps to remove all impurities and contaminants. A key part of this is the filtration system schematic, which shows each stage of treatment.

This schematic helps us ensure the water is as clean as possible. It guides us in following the right steps for purification.

A water purification diagram is also crucial. It visually shows the different parts and stages of the process. This makes it easier to spot areas for improvement and fine-tune the system.

Our team uses these diagrams to create post-treatment systems that fit our clients’ needs perfectly.

Some main benefits of our systems include:

- High-quality water purification

- Effective removal of impurities and contaminants

- Improved water taste and odor

- Increased water safety

By using a well-designed filtration system schematic and water purification diagram, we achieve the best results. Our team is dedicated to offering top-notch water purification solutions for our clients.

Advanced Control Systems and Automation

Our advanced control systems make sure your reverse osmosis plant runs smoothly and efficiently. The ro plant layout design is key to the system’s success. Digital monitoring helps us improve the water treatment process, cutting down on mistakes and boosting productivity.

The system’s design is flexible, fitting into any RO plant size. It’s perfect for many uses. Our control systems have some standout features:

- Real-time monitoring of important factors like power, efficiency, and water levels

- Early warnings for issues like power failures, membrane problems, and water shortages

- System-predicted maintenance tasks, like cleaning the membranes

Machine learning on sensor data helps us forecast maintenance needs. This cuts down on unexpected downtime. The RO membrane’s performance depends on the water quality and plant conditions. Our systems offer an easy-to-use interface for operators to keep an eye on things.

Using predictive maintenance tools can cut downtime by 20%. This saves a lot of money. With these advanced systems, our reverse osmosis plant is a valuable asset for any industry.

Environmental Impact and Sustainability Features

We aim to provide clean drinking water for everyone. This means we must think about how our methods affect the environment. Our systems are made to cut down on waste and use energy wisely, following the reverse osmosis plant diagram. This way, we lower the carbon footprint of our work.

Here are some important facts about water and sustainability:

- 40% of the global population is experiencing severe freshwater shortages.

- 97.5% of the planet’s water is salt water from oceans, leaving only 2.5% as freshwater.

- Global water needs are projected to increase from 4,500 billion cubic meters to 6,900 billion cubic meters by 2030.

To lessen our environmental impact, we design our reverse osmosis systems with sustainability in mind. We use renewable energy, cut down on chemicals, and make our pre-treatment and post-treatment processes efficient. This helps us reduce our environmental load and make the planet healthier for the future.

Industrial Applications and Case Studies

Our systems have been used in many places, like factories, water treatment plants, and big buildings. A water purification diagram is key to understanding how reverse osmosis works. It shows the important parts of the system, making it simpler to keep and use.

Using reverse osmosis systems has many advantages. They can remove almost all salts and harmful substances from water. They can handle water with up to 5,000 parts per million (ppm) of dissolved solids. The systems work best when the water is not too hot, and they need a certain pressure to operate.

Here are some key features of industrial reverse osmosis systems:

- High-quality water production

- Low operating costs

- Compact design

- Easy maintenance

In conclusion, industrial reverse osmosis systems are a solid choice for water purification. By knowing the ro plant components visualization and using a water purification diagram, industries can get clean water and save money.

Quality Assurance and Compliance Standards

Our systems are built to meet top quality standards, ensuring clean water. A key part of this is the ro system diagram for water treatment. It shows how the system is set up. Knowing the reverse osmosis definition is also important. It helps remove bad stuff from water.

Reverse osmosis systems have strict quality rules. They must keep microbiological contamination under 10 CFU/100 mL. Our systems are made and run to meet or beat these rules. Here are some key standards for reverse osmosis systems:

| Standard | Acceptable Limit |

|---|---|

| Microbiological Contamination | Less than 10 CFU/100 mL |

| Total Dissolved Solids (TDS) | Less than 10 ppm |

| Endotoxins | Less than 0.25 EU/mL |

By following these standards, our systems offer a trusted way to treat water. They ensure water is as pure and safe as possible.

Future Innovations in Plant Design

Our company is always looking to improve reverse osmosis systems. We focus on new technologies and ways to make them more efficient. The future of ro plant layout design will bring better filtration systems, making water treatment more effective.

Key areas for innovation include better membranes, improved pretreatment, and advanced automation. These changes will make reverse osmosis systems work better. They will use less energy and cost less, while also improving water quality.

For instance, tighter filters can cut down on membrane fouling. Multimedia filters can also reduce suspended solids. Chemical coagulants and scale inhibitors help prevent scale and protect membranes.

These innovations offer many benefits:

- Improved water quality

- Increased efficiency and reduced energy consumption

- Reduced maintenance and operating costs

- Increased system reliability and uptime

Looking ahead, reverse osmosis systems will be crucial for meeting global water needs. By innovating and improving these systems, we ensure a sustainable future.

| Technology | Benefits |

|---|---|

| Advanced membranes | Improved efficiency, reduced energy consumption |

| Pretreatment systems | Reduced membrane fouling, improved water quality |

| Automation and control systems | Improved system reliability, reduced maintenance costs |

Conclusion

We are dedicated to offering top-notch water treatment solutions. Our reverse osmosis (RO) plant diagrams and RO system infographics highlight our advanced technology. This technology is key to our water purification systems.

The RO process is very effective at removing harmful substances from water. Our systems can handle water at various rates, from 25 gallons per hour to over 450,000 gallons daily. They can even recover more than 90% of the water, thanks to our advanced technology.

We work hard to meet the specific needs of our clients. This includes industrial, municipal, and commercial sectors. Our team is always looking for new ways to improve our RO plant designs. We aim to make our systems more efficient and environmentally friendly.

We are leaders in this field, pushing the boundaries of water treatment. Our goal is to help create a more sustainable future. We are committed to making a positive impact through our work.