Understanding Water Treatment Plant process is essential. In our modern world, access to clean and safe drinking water is a necessity. Water treatment plants play a crucial role in ensuring that the water we consume meets the highest standards of quality and safety. Through various processes and technologies, these plants remove impurities, contaminants, and harmful microorganisms from the water, making it suitable for consumption. In this comprehensive guide, we will explore the step-by-step journey of water through a typical water treatment plant process, from its initial collection to the final distribution to our homes and businesses.

1. Collection of Water Sources

The water treatment plant process begins with the collection of water from various sources, such as rivers, reservoirs, or underground aquifers. These sources may vary depending on the location and availability of water resources. The quality of the source water can also differ, necessitating specific treatment methods to ensure its safety.

2. Screening and Intake

Once the water has been collected, it undergoes a preliminary screening process to remove large debris, such as leaves, twigs, and other floating materials. Coarse screens and fine screens are utilized to effectively separate these impurities from the water. Coarse screens consist of corrosion-resistant steel bars spaced apart to exclude larger materials, while fine screens, including micro strainers, catch smaller particles as small as algae and plankton in water treatment plant process.

3. Aeration and Pre-Chlorination

After the screening process, the water enters the treatment plant, where it undergoes aeration. Aeration involves supplying air to the water to remove dissolved gases, such as carbon dioxide and hydrogen sulfide. So, this process helps reduce the water’s corrosiveness and eliminate any undesirable taste or odor caused by gaseous organic compounds. In some cases, pre-chlorination is employed to address excess algae growth, which can clog downstream filters. Meanwhile, chlorination kills algae and oxidizes taste- and odor-causing compounds in water treatment plant process.

4. Coagulation and Flocculation

Following aeration and pre-chlorination, the water proceeds to the coagulation and flocculation stage. In this step, a coagulant, such as aluminum sulfate or ferric chloride, is added to the water to neutralize the negative charge of fine particles suspended in the water. The coagulant causes these particles to clump together and form larger aggregates called flocs, accordingly. Hence, flocculation, achieved through gentle stirring in flocculation basins, allows the flocs to grow in size, facilitating their removal in subsequent steps. So, you can use CHUNKE dosing system in water treatment plant process.

5. Sedimentation

After flocculation, the water enters sedimentation basins, where the flocs settle to the bottom due to their increased weight. So, this process, known as sedimentation or clarification, allows the separation of the heavier particles from the water. Hence, the settled particles, known as sludge, are removed for disposal, while the clarified water moves forward in the treatment process.

6. Filtration

To further purify the water, it undergoes filtration. Filtration involves passing the water through various filter media, such as sand, gravel, anthracite, and activated carbon. Hence, these filters remove remaining suspended particles, microorganisms, and dissolved impurities that may have escaped the sedimentation process. Different types of filters, including rapid gravity sand filters and multi-media filters, are employed to achieve optimal purification.

7. Disinfection

Once the water has been filtered, it proceeds to the disinfection stage, where any remaining pathogenic microorganisms are eliminated. Chlorine, chlorine dioxide, or a combination of chlorine and ammonia, known as chloramines, are commonly used disinfectants. These chemicals effectively kill bacteria, viruses, and other harmful organisms, ensuring that the water is safe for consumption. Additionally, fluoride is often added to support dental health by preventing tooth decay.

8. Advanced Treatment Techniques

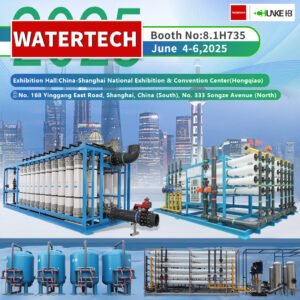

In addition to the primary treatment processes described above, some water treatment plants employ advanced techniques to further enhance water quality. So, two notable methods include reverse osmosis (RO) and ultrafiltration. RO involves passing water through a membrane with extremely small pores to remove additional particles and impurities. Meanwhile, this process is particularly useful for treating recycled water or desalinating saltwater for drinking purposes. Ultrafiltration, on the other hand, utilizes a filter membrane with small pores to separate water from larger molecules, salts, and charged particles.

9. UV Sterilization and Ozone Treatment

In certain cases, water treatment plants utilize ultraviolet (UV) sterilization or ozone treatment as alternative disinfection methods in water treatment plant process. UV light and ozone are effective in killing germs and microorganisms present in the water. So, UV light disinfects the water by damaging the genetic material of microorganisms, rendering them unable to reproduce. Also, Ozone, a powerful oxidizing agent, kills microorganisms through chemical reactions. These advanced treatment techniques provide an additional layer of protection and ensure the highest level of water safety, accordingly.

10. Distribution of Treated Water

Once the water has undergone the necessary treatment processes, it is ready for distribution to homes, businesses, and other end-users. Treated water is pumped into a network of pipes that transport it to its final destination, accordingly.

Why Do We Need Advanced Technics

In our time, we are using so many chemicals, plastics, electronics, pesticides, insecticides and so on. All of them are contaminate and go inside our water source. Meanwhile, Scientists has made research for microplastics in human bodys, You can read article, they discover, newborn baby has microplastic in its blood. So, most of scientist suggest Ultrafiltration and Reverse Osmosis Systems to purify and filter your source water.

What is Ultrafiltration System?

Ultrafiltration is a separation process that uses a semi-permeable membrane to purify and separate substances based on their molecular size. It is commonly using in water treatment, pharmaceuticals, and food industries. The process involves forcing a fluid, often water, through the membrane at high pressure. So, the membrane has tiny pores that allow water and small molecules to pass through while blocking larger particles, such as suspended solids, bacteria, and some viruses. This results in the removal of impurities and contaminants, producing clean and clarified water or a concentrated solution, depending on the specific application. Ultrafiltration is an effective method for achieving high-quality water purification and separation of substances at a molecular level.

What is Reverse Osmosis System?

Reverse osmosis (RO) is a water purification process that utilizes a semi-permeable membrane to remove dissolved salts, contaminants, and impurities from water. The system works by applying pressure to the water, forcing it to pass through the membrane, which has extremely small pores that only allow water molecules to pass through.

During the reverse osmosis process, the water’s impurities, such as salts, minerals, and other contaminants, are left behind and flushed away as wastewater. The purified water that successfully passes through the membrane collects on the other side, resulting in clean, purified water suitable for various applications, including drinking, industrial use, and other specialized processes.

Reverse osmosis is highly effective in producing high-quality, low-impurity water, making it a widely used method for water treatment and desalination in both residential and industrial settings.

Industrial Reverse Osmosis Plant for Tap Water

Industrial Reverse Osmosis Plant for Brackish Water

Industrial Reverse Osmosis Plant for Sea Water