Today, we will explain why Reverse Osmosis for Boiler Feed Water is so important. In industrial facilities that rely on boilers for their operations, it is crucial to have a reliable and efficient boiler feed water treatment system in place. The quality of the feed water directly affects the performance and lifespan of the boiler, and can significantly impact operational costs. One of the most effective and innovative methods of boiler feed water pretreatment is reverse osmosis (RO). In this comprehensive guide, we will explore the advantages of using reverse osmosis for boiler feed water pretreatment, as well as its impact on scaling, alkalinity, and corrosion issues.

Understanding Boiler Feed Water Treatment

Before diving into the specifics of reverse osmosis for boiler feed water pretreatment, it is essential to grasp the concept of boiler feed water treatment systems. These systems are designed to remove impurities from the water, such as dissolved and suspended solids, organic materials, and minerals that can lead to scaling, fouling, and corrosion of the boiler and downstream equipment. A well-designed boiler feed water treatment system not only ensures the generation of high-quality steam but also helps prevent costly plant downtime and maintenance fees.

The Role of Reverse Osmosis in Boiler Feed Water Treatment

Reverse osmosis is a highly effective process used to extract impurities and minerals from water. It is commonly employed to convert seawater or brackish water into fresh water and improve the taste and quality of drinking water. When applied to boiler feed water treatment, reverse osmosis serves two crucial purposes. Firstly, it purifies the water, making it suitable for cooking, drinking, and other applications that require high water quality. Secondly, it protects the boiler from mineral buildup, which can lead to scaling, obstructions, and decreased efficiency or even failure of the system.

What Does a Boiler Feed Water Treatment System Typically Remove

– Calcium and magnesium: causes scaling of the boiler feed water.

– Silica: known to cause hard scaling. Silica needs to be reduced to low levels to avoid any operating issues.

– Iron and manganese: can damage downstream equipment and have an affect on the quality of the water.

– Copper: decreases the efficiency of boiler feed equipment when deposited in high-pressure turbines.

– Magnesium: has the ability to stick to the inside of the boiler, also causing scaling.

– Hardness: causes scaling on boiler piping.

– Aluminum: can react with silica to increase scaling.

– Dissolved gases: can cause severe corrosion to the boiler due to oxygen and carbon dioxide presence.

Addressing Scaling Problems with Reverse Osmosis

Scaling is a common issue in boilers caused by the accumulation of minerals, such as calcium, magnesium, and silica, on the internal surfaces. These scales restrict heat transfer, impairing the efficiency of the boiler and increasing energy consumption. Reverse osmosis effectively removes these scale-forming minerals, preventing their deposition in the boiler and ensuring optimal heat transfer. By implementing reverse osmosis for boiler feed water pretreatment, facilities can significantly reduce scaling problems, leading to improved boiler performance and reduced energy costs.

Alkalinity Problem and the Solution Provided by Reverse Osmosis

Alkalinity in boiler feed water can lead to various issues, including foaming, corrosion, and embrittlement of boiler components. Reverse osmosis plays a crucial role in controlling and reducing feedwater alkalinity. By removing bicarbonates, sulfates, and nitrates, reverse osmosis helps lower the alkalinity levels, mitigating the risk of these problems. It provides an economical and effective solution for adjusting the pH of the boiler feed water and ensuring optimal boiler operation.

Combating Corrosion in Boilers through Reverse Osmosis

Corrosion is a significant concern in boiler systems, as it can lead to equipment failure, leaks, and costly repairs. Reverse osmosis plays a vital role in combating corrosion by removing dissolved gases, such as oxygen and carbon dioxide, from the feedwater. These gases, when present in high concentrations, can cause severe corrosion on boiler pipes and parts. By eliminating them to acceptable levels, reverse osmosis helps prolong the service life of the boiler and ensures its safe and efficient operation.

Advantages of Reverse Osmosis for Boiler Feed Water Pretreatment

Utilizing reverse osmosis for boiler feed water pretreatment offers numerous advantages for industrial facilities:

- Substantial Reduction in Scaling and Fouling: Reverse osmosis effectively removes scale-forming minerals and other impurities from the feedwater, reducing scaling and fouling issues in the boiler and downstream equipment.

- Improved Boiler Efficiency: By preventing scaling, fouling, and corrosion, reverse osmosis helps maintain optimal heat transfer and boiler efficiency, resulting in reduced energy consumption and operating costs.

- Enhanced Steam Quality: Reverse osmosis ensures the production of high-quality steam, free from impurities and contaminants. This improves overall process efficiency and product quality.

- Extended Equipment Lifespan: With the elimination of scaling, fouling, and corrosion, the lifespan of the boiler and downstream equipment is significantly extended, reducing the need for frequent repairs and replacements.

- Cost Savings: The reduction in energy consumption, chemical usage, and maintenance requirements associated with reverse osmosis leads to substantial cost savings for the facility.

Implementing Reverse Osmosis for Boiler Feed Water Pretreatment

To implement reverse osmosis for boiler feed water pretreatment, a comprehensive treatment system is required. This system typically includes various components and processes, such as filtration, ion exchange, membrane processes (such as reverse osmosis and nanofiltration), deaeration/degasification, and coagulation/chemical precipitation. The specific configuration of the system will depend on the quality of the water source and the manufacturer’s recommendations.

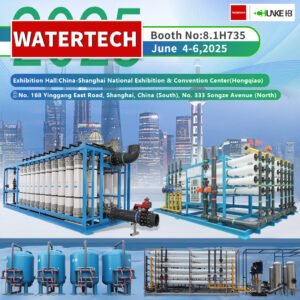

The Role of Chunke Water Treatment in Boiler Feed Water Pretreatment

Chunke Water Treatment specializes in providing complete solutions for boiler feed water applications, including reverse osmosis systems. Their expertise and experience in water treatment ensure that industrial facilities receive the most efficient and reliable systems tailored to their specific needs. By partnering with Chunke Water Treatment, facilities can reduce energy costs, scaling, and corrosion, while ensuring the production of high-quality steam and maximizing operational efficiency.

Conclusion

In conclusion, reverse osmosis offers an excellent solution for boiler feed water pretreatment. By effectively removing impurities, minerals, and gases, it helps combat scaling, alkalinity problems, and corrosion in boilers. With its numerous advantages, including improved boiler efficiency, extended equipment lifespan, and cost savings, reverse osmosis is a valuable investment for industrial facilities. By partnering with experts like Chunke Water Treatment, facilities can ensure the implementation of a comprehensive and customized boiler feed water treatment system, optimizing their operations and ensuring long-term success.