Well Water Filtration System is a method used to filter out undesired chemical compounds, organic and inorganic materials, and biological contaminants from water supplies. So, the purpose of water filtration is to provide clean drinking water or treated water for commercial and industrial process.

What Is the Types of Well Water Filtration System

Well Water Filtration System types are dependent on water analysis report. We suggest you to send one bottle of well water to labrotay and get water analysis report. As regards to this analysis report, we can suggest and design well water filtration system accordingly.

Chunke Well Water Filtration System Types:

1. Sand Filters

2. Iron Filters

3. Multi-media Filters

4. Activated Carbon Filters

5. Water Softeners

6. Reverse Osmosis systems

7. Ultrafiltration Systems

8. Cartridge and Bag Filters

9. UV Filters

What Is the Best Well Water Filtration System for Your Well?

After we get your water analysis report, we will check all organic and inorganic matters in your water. Experts decide systems, after checking water testing report. Because well can have iron, salt, organic suspended solids, inorganic suspended solids, dangerous chemicals like arsenic, bacteria and viruses. Your well water can have all of them or some of them.

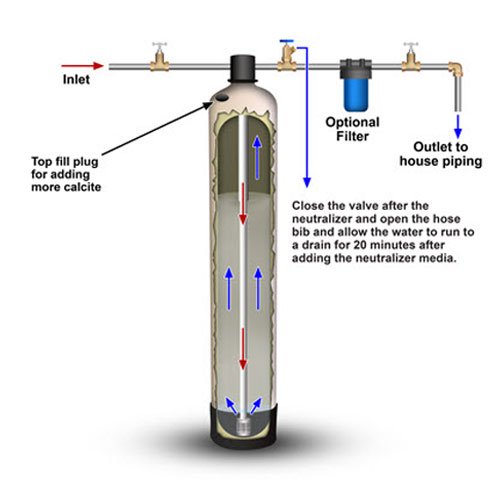

Sand Filters

Sand filtration system removes contaminants, suspended matter, as well as floating and sinkable particles. The wastewater flows vertically through a fine bed of sand and/or gravel. Particles are removed by way of absorption or physical encapsulation. If there is excessive pressure loss on the filter, it must be rinsed.

A distinction can be made between continuous and discontinuous filters. Hence, in continuous filters (often upward-flowing filters), the polluted sand is removed, rinsed and re-used continuously, without interrupting the filtration process. Discontinuous filters (often downward-flowing filters) are stopped, and a rinse takes place in the opposite direction. So, aAir bubbles are blown into the sand bed to make it swirl around. Filtered water then passing through the filter bed in the opposite direction. The polluted matter is released and flows away along with the rinse water. The filtration process can then resume.

The yield of a sand filtration system is determined by two sand filter functions, namely surface filtration and depth filtration. Surface filtration involves collecting the particles above the filter bed. So, these particles jointly form a macro-porous lump, which is able to collect new particles in a very effective manner. Depth filtration generally involves smaller particles that are more difficult to collect, and which are bound to the sand particles by adsorption. Dirt from surface filtration is easier to remove during reverse rinsing compared to dirt from depth filtration.

Iron Filters

The iron filtration unit contains a “media bed,” like a water softener, but in this case, the media is not resin but an oxidizing agent such as manganese dioxide. When water passes through the bed, the media attracts soluble ferrous iron and converts it to an insoluble state. That allows a filter to capture the iron precipitate, leaving the water iron-free. The system is maintained with periodic backwashing to remove the precipitated iron and, less frequently, regeneration to refresh the oxidizing ability of the media bed.

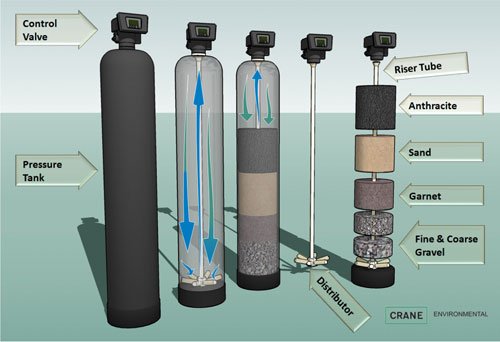

Multi-media Filters

Multimedia filtration refers to a pressure filter vessel which utilizes three or more different media as opposed to a “sand filter” that typically uses one grade of sand alone as the filtration media. In a single media filter, during the “settling” cycle, the finest or smallest media particles remain on top of the media bed while the larger, and heavier particles, stratify proportional to their mass lower in the filter. This results in very limited use of the media depth since virtually all filterable particles are trapped at the very top of the filter bed or within 1-2 inches of the top where the filter media particles have the least space between them. So, the filter run times are thus very short before the filter “blinds” or develops so much head pressure that it must be backwashed to avoid seriously impeding or stopping the flow. So, multi-media filter removes contaminants.

Multi-media water filters typically utilize three layers of media for multimedia filtration: anthracite, sand and garnet. These media are often chosen for use in multimedia filters due to the distinct differences in their densities. Meanwhile, anthracite is the lightest filtration media per unit volume, followed by sand, and then garnet.

More Details

The idea behind using media with differing masses is that during backwashing the lightest media with the largest particles (anthracite). It will naturally stratify at the top of the filter, while the intermediate sized media (sand) will settle in the middle, and the heaviest media with the smallest particles (garnet) will settle to the bottom.

This layering of the filtration bed encourages the very largest contaminants to become trapped in the first layer of the filter, with smaller particulates sifting farther down into the lower layers. So, trapping contaminants in this manner allows for more efficient turbidity removal and for longer run times between backwash cycles. A simple sand filter can be expected to eliminate particles down to 25-50 microns in size, as compared to a multimedia filter that can remove particles down to 10-25 microns.

Operating at higher pressure differential is liable to drive particles so deeply into the media bed that backwash is not able to remove them all. Over time the build-up of dirt deep in the filter will cause shortened filter runs and high differential pressures. Filter backwash may include air scour to help loosen packed dirt in the media bed. When this step is included, it is preceded in the backwash cycle by a “drain down” period for water to be bled out of the filter vessel.

Flocculants / coagulants may be used upstream of the filter to induce the tiny dirt particles to join together to form particles large enough to be removed by the filter. This process is called “agglomeration” and, with proper chemical dosage, adequate mixing and adequate contact time, it will enable the filter to remove particles below 10 microns in average diameter.

Activated Carbon Filters

Activated carbon filters are generally employed in the process of removing organic compounds and/or extracting free chlorine from water, thereby making the water suitable for discharge or use in manufacturing processes. Eliminating organics in potable water, such as humic and fulvic acid, prevents chlorine in the water from chemically reacting with the acids and forming trihalomethanes, a class of known carcinogens.

Activated Carbon (AC) filtration, as with any water treatment method, is not capable of removing every possible type of contaminant. For example, sodium, microbes, fluoride, and nitrates cannot be removed with AC filtration. Water softening also cannot be achieved with AC filters. In addition, heavy metals, such as lead, can only be removed with a very specific kind of activated carbon water treatment, which is typically used only in residential point-of-use filters.

Applications:

There are many of applications for Activated Carbon Filters. Only some of them which are most important & common are listed below.

- Free Chlorine Removal

- Organic Matter removal

- Odor and Taste Removal

- Bromate Removal (After Ozonation of SWRO Permeate)

- De-colourisation of Sugar Melt (White Sugar Manufacturing)

- De-colourisation of Molasses

- Air Purification

- Catalyst Carrier

- Flue gas purification (Dioxin & Mercury Removal)

Water Softeners

A water softener is ion-exchange process that removes hardness-causing calcium and magnesium minerals from your water through a process called ion exchange. A water softener addresses one of the most prevalent and devastating water problems: hard water. Hard water creates a lot of problems at home water and industrial processes. Scale builds up in your pipes, clogging them and decreasing water pressure. Scale dramatically shortens the lifespan of appliances and machines like dishwashers, coffee makers, boilers and cooling towers. Hard water destroys hot water appliances and equipment.

The higher the temperature of the water, the more calcium and magnesium will solidify and harden into solid deposits inside your hot water heater or boiler. If you live in hard water territory, it can sound like your water heater is popping popcorn. This is because scale has attached itself to the heating element. As the temperature of the heater rises and the tank expands, the calcified rock deposits crusted on the heating elements start cracking and stretching. Hard water-induced scale is the culprit of that popcorn popping sound.

Reverse Osmosis Systems

Reverse osmosis units are high level water treatment units in which high technology means are put into use.

Reverse Osmosis is a water purification process in which feed water is processed through a membranes. This membrane stop contaminated water, cleaning solutions and undissolved materials from passing through. So, the clean water is sent along to the point of use and the containments are discharged to a drain. The process, combined with pre-filtration, is able to remove 90 to 99.99% of the dissolved impurities that reside in your water.

Reverse osmosis (RO) is a water purification technology that uses a semipermeable membrane to remove ions, molecules, and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pressure, a colligative property, that is driven by chemical potential differences of the solvent, a thermodynamic parameter. Reverse osmosis can remove many types of dissolved and suspended species from water, including bacteria, and is used in both industrial processes and the production of potable water. And increase water quality. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be “selective”, this membrane should not allow large molecules or ions through the pores (holes), but should allow smaller components of the solution (such as solvent molecules) to pass freely.

Ultrafiltration Systems

Ultrafiltration is a water treatment process that uses a hollow fiber or a sheet membrane to mechanically filter water containing very small particulate. An ultrafiltration drinking water system uses this super fine membrane technology to filter particulate down to 0.025 microns. To help you get an idea just how small that is, the diameter of a human hair is typically about 75-80 microns. Hence, this means that an ultrafiltration system works on a micro level, literally taking all suspended solids out of the water.

Cartridge and Bag filters

Cartridge filters are preferable for water filter systems with contaminations lower than 100 ppm, that is to say with contamination levels lower than 0.01% in weight accordingly.

Cartridge Filters

Cartridge filter can be surface or depth-type filter: depth-type filters capture particles and contaminant through the total thickness of the medium, while in surface filters (that are usually made of thin materials like papers, woven wire, cloths) particles are blocked on the surface of the filter.

Surface filters are best if you are filtering sediment of similar-sized particles. If all particles are i.e. five micron, a pleated 5-micron filter works best because it has more surface area than other filters. Meanwhile, compared with pleated surface filters, depth filters have a limited surface area, but they have the advantage of depth.

It can be generally stated that if the size of filter surface is increased, higher flows are possible, the filter last longer, and the dirt holding capacity increases. Cartridge filters are normally designed disposable: this means that they have to be replaced when the filter is clogged accordingly.

Bag Filters

Bag filters are in general frequently used for dust removal in industrial applications. The flow can be from the outside to the inside of the filter (that means, the separation of particles happens on the external surface of the filter) or the other way around, depending on the application. The particles are normally captured on the internal surface of the bag filter.

Bag filters are in general not designed for replacement when they are clogged, but some bag filters for gaseous applications like dust removal can be cleaned, for example by mechanical shaking or by backwashing with compressed air (so called reverse-flow bag filters).

UV Water Filters (Ultraviolet Sterilizer)

The UV water disinfection process utilizes special UV lamps that emit UV light of a particular wavelength. These UV light waves have the ability, based on their length, to disrupt the DNA of microorganisms. So, these UV light waves are referred to as the Germicidal Spectrum or Frequency, the frequency used in killing micro-organisms is 254 nanometers (nm).

During the UV water disinfection process, as water passes through a UV water treatment system, living organisms in water are exposed to UV light which attacks the genetic code of the microorganism and rearranges the DNA /RNA, eliminating the microorganism’s ability to function and reproduce.

If a microorganism can no longer reproduce, it cannot replicate, therefore it cannot infect other organisms with which it has contact. This process of exposing water to UV light is simple, effective, and destroys 99.99% of harmful microorganisms without adding any chemicals to water.

Best Well Water Filter Systems for House or Home

The best way to treat well water, is with an ultraviolet (UV) water disinfection system. UV filtration is becoming increasingly popular as a whole-house water treatment system for private well owners as UV water sterilizers can effectively remove 99.99% of viruses, bacteria and other microbes from water.

UV water filters are safe, powerful, economical, and require very little maintenance. Best of all, a whole-house UV disinfection system works night and day, 24/7, consistently keeping your water safe–without you having to constantly test your well water!

Because well water often has a high level of dissolved solids and organic matter, we recommend installing a sediment filter in front of the UV system. Another option is to select a UV system that includes an integrated prefilter, which prepares the water for the ultraviolet disinfection process. If a prefilter is NOT used and the turbidity level is high, the UV rays will be blocked by particles in the water making the UV treatment process less effective. (Turbidity is the quantity of suspended solids in water which often causes cloudiness.)

While all UV Water Purification Systems will work for well water applications, most well owners have the best success when they install a prefilter or combination sediment and carbon prefilters to prepare the well water for UV treatment in an all in one system. chunke has wide range house water filters.

How Much Is Water Filtration System for Well Water?

Well Water Filtration system price is dependent on your water analysis report and flow rate as liter per hour or gallons per minute. Therefore, to give you exact price, we have to get more details.

To get more information please fill in form and our technical sales team contact with you in 24 hours and provide to you the best well water filtration system and other filtration systems.